Improving Supplier Performance – Defining Service Improvements

What we deliver – Service Improvements

-

Facilitated internal agreement of service improvements required. Our proven approach to facilitate between all internal stakeholders, the specific performance improvements you need from the supplier, taking into account any competing internal business priorities and time scales.

How you will benefit

-

Reduces stakeholder uncertainty. The facilitation process and clarity of competing issues priorities, puts key stakeholders at ease.

-

Improved supplier visibility and advice. The Supplier gets much greater visibility of your expectations to provide you with a better aligned service improvement plan.

-

Fit for purpose certainty. Provides the foundations to contractually hold Suppliers accountable for agreed service improvements on an agreed and informed basis.

How the best organisations identify issues for improvement

A summary of the approach to take to identify the right issues

The key issue in fixing poor supplier performance for complex services/solutions, is identifying the actual cause. In fact, there are often several causes, some of which may result from your own team’s actions and some from the strategic supplier’s actions.

The evidence you document as a result of your investigations will assist you in future discussions with your strategic supplier and help you to work with them to significantly improve service performance, rebuild trust in the relationship and achieve your business outcomes.

It’s important the steps below are agreed upon internally with your own management and operations teams so that when you approach the supplier to improve issues, your internal team all approach matters from an agreed perspective. Any ‘breaking from the ranks’ is likely to lead to the supplier becoming confused about which specific issues need to be dealt with, in which priority and by when. The key steps are:

- Step 1 : Evidence your original expectations from your business case

- Step 2 : Identify the specific expectations documented in the contract

- Step 3 : Quantify any unexpected costs incurred from poor performance

- Step 4 : Objectively identify your responsibilities to each other

- Step 5 : Clarify your objectives to rebuild trust with the supplier

- Step 6 : Think through the context of the challenges being experienced

- Step 7 : Sanity check your observations and approach

- Step 8 : Schedule the issues/challenges in chronological order.

Step 1 : Evidence your original expectations from your business case

As projects/services get implemented, we find that internal stakeholders focus on the problems/challenges being experienced from the supplier.

There can often be misinterpretations and misunderstandings from the internal client stakeholders as to what the original business outcomes expected were from the service/solution in the business case.

For completeness, we’ll often go back to the original business case to check:

- The original business benefits internal stakeholders signed up to. This provides better objectivity for all concerned.

- Whether the stakeholders (or the supplier) perceives those objectives have changed or moved on since the business case was agreed and the service / solution implementation was commenced.

- What were the specific operational improvements expected?

Step 2 : Identify the specific expectations documented in the contract

Once we have reviewed the business case (Step 1), we will then be in a position to check how these are reflected in the written contract terms. We’ll often check:

- Whether all of the schedules (i.e. your requirements, expectations, implementation plan and so forth) are specifically referenced in the written contract.

- How the written contract was developed is also important here. If the contract was:

- Negotiated from scratch, then the contract terms are unlikely to help you to rebuild trust if they can be interpreted too widely.

- The vendor’s standards terms without modification, then it will be easier to deal with the ramifications of terms that might not work in your favour, when rebuilding trust

- The vendor’s standard terms with some modification, then dealing with the ramifications can involve more detailed work, but the contract can still be aligned with rebuilding trust.

As a double check, we’ll also identify if the contract was actually signed by both you and the supplier? We occasionally see contract terms that have been agreed but not signed, or that schedules haven’t been attached. This can cause misunderstandings that undermine trust going forward.

Step 3 : Quantify any unexpected costs incurred from poor performance

After we have conducted the first two Steps above, we will then need to quantify the financial costs you have incurred, as a result of your supplier’s inability to achieve your objectives.

Note, although this Step can be used as part of a subsequent process to formalise and/or pursue a financial claim against your supplier, that isn’t its primary objective at this stage.

The primary objective of this Step is to ensure you have as much practical transparency of what the supplier performance challenges are costing you in real terms. Internal stakeholders are often frustrated at complex services/solutions having their implementation delayed, but usually do not have any real visibility or transparency of the real financial impact on the organisation of these delays.

As a result, the supplier is also unlikely to have visibility of the specifics of the additional costs you are incurring. Therefore, part of the purpose of quantifying these costs, is so the supplier understands the seriousness of the financial consequences their implementation delays are having on your organisation, and that if they are unable to remediate matters in an optimum time frame, you will be able to claim these costs for delay against them.

This often helps to focus the supplier’s mind to put their own appropriate resources into place to remediate matters promptly.

The areas of additional cost often include:

- The time you have spent working with the supplier to address performance issues

- The costs of external advisors you have had to engage

- The costs of existing service delivery lines/solutions you have had to continue operating

- Any legacy system, maintenance and development costs you have had to continue incurring

- The costs of interim or temporary staff you have had to employ, to keep performance at a reasonable level.

Step 4 : Objectively identify your responsibilities to each other

A vital step in understanding the cause of poor performance is to ascertain who was contractually responsible for key aspects of the relationship.

- Firstly, we’ll review who was responsible for project management in the written contract terms?

- Then we’ll look at what the supplier’s role was in managing the project, and how did your own people participate in managing the written contract?

- Was it a term of the written contract that there would be a true ‘partnership’ approach to managing the relationship?

Next, we’ll determine the extent to which you relied on your supplier’s “expert” advice. This has a key bearing on the their ‘Expert Responsibilities”:

- Did you rely on the supplier’s advice as to the benefits the relationship would bring to your organisation?

- If so, are there any documents to evidence that you had this reliance?

- Alternatively, were you happy that you undertook enough due diligence on the supplier that you did not need to rely on its advice?

Step 5 : Clarify your objectives to rebuild trust with the supplier

To rebuild trust with your supplier, it’s important to have clear objectives in mind. We will discuss with you what you believe is an appropriate outcome from bringing these issues to a head? Is it to:

- Get the supplier to resolve the issues you’re experiencing, and prevent further issues arising?

- Resolve the problems and get compensation or reduced fees for a suitable period?

- Buy you time to put a contingency supplier in place for aspects of the service that are not performing? You would normally want to retain the existing supplier for the services they deliver well.

We will also discuss that your chances of rebuilding the relationship and improving performance are enhanced if you also consider the supplier’s position in your planning. for example, what do you think the supplier would consider an appropriate solution to the current dilemma?

In summary, what would it take to satisfy you and what do you think would be a fair and equitable solution?

Step 6 : Think through the context of the challenges being experienced

In addition to the points we’ve listed in the previous bullet items, there are a number of general points that we’ll need to discuss with you.

- The degree to which you internally believe that both you and your supplier need to change behaviours, in order to rebuild trust in your relationship. Or whether, despite your best intentions, your supplier has been unable to reasonably improve its own approach and behaviours.

- Did your supplier warn you before you entered into the contract, whether it was likely to have difficulties meeting your business outcomes?

- Was it your perception that time was of the essence in achieving the business outcomes from the relationship? Note this can be validated by checking other aspects of documentation in addition to the written contract.

- Do you think it’s possible that some of the performance issues experienced, could have been as a result of your own team not doing what was expected by the supplier, at the appropriate time?

- Whether you have a perception the supplier should have asked more questions about your expectations, to ensure your business outcomes could be fulfilled? If so in which areas?

- Could the supplier have undertaken more appropriate due diligence on the business outcomes you were trying to achieve?

- If so, have you had any conversations with your supplier where it was inferred they could have provided better advice to you of the compromises you would have to face, before they accepted the agreement or providing you with their services?

- When the supplier was originally investigating how it might achieve your business outcomes, were all of your responses to its questions factually correct?

Next, consider why the supplier has failed to deliver your expected business outcomes.

- Could there be more than one cause of the symptoms you’re experiencing?

- Were your expectations not quantified or sufficiently transparent for your supplier to be able to understand them?

- Note that this does not let the vendor ‘off the hook’ if it has misunderstood your expectations.

- Its “Expert Responsibilities” required it to identify any of your requirements that were unclear. If this was the case, your supplier should have warned you about this pre- contractually, so you could make an informed decision about how it was approaching its due diligence.

- If your supplier didn’t warn you, it is up to the supplier to remedy the position and meet your business outcomes, bearing any additional cost itself.

Communication with your vendor about the issues you’re experiencing is another key point we will usually look at.

- Have you been communicating the problems to the supplier on a regular basis, in writing (email or hard copy).

- Do you know whether you have escalated those issues in line with the procedure in your written contract terms?

- Do you have a formal issues log, with supplier acknowledgements, of the problems being experienced?

Finally, we’ ll be discussing your views of what you consider to be the current state of your relationship with your supplier. for example, some of the additional points will include :

- How strong do you perceive the strategic supplier relationship to be?

- Whether you have withheld payment for invoices that you dispute due to the level of performance provided?

- If so, for what services specifically?

Step 7 : Sanity check your observations and approach

By our reviewing the key issues and your approach, this will assist your internal stakeholders to know from an independent assurance perspective, whether your internal perception of events is evidentially robust.

Once your evidence has been gathered, the next step is to determine the degree to which it aligns with the perception of your internal stakeholders. Having reviewed and sanity checked the evidence, we’ll be able to advise you of :

- Where you have fulfilled your obligations to the supplier and, albeit inadvertently, where you have not.

- Where the supplier has provided good business outcomes and where it has not.

At the end of the sanity checking stage, will know whether the evidence collated is a fair reflection of both your and your supplier’s performance in the relationship.

Note that evidence is often imperfect. All you are looking for is whether, on balance, the evidence reflects that your expected business outcomes have been achieved or not, and whether your own team has materially hampered the supplier in preventing the delivery of those outcomes in any way.

You will also have a much clearer idea of whether your supplier has discharged its “Expert Responsibilities”, including its “Duty to Warn” you of issues that, in its experience, may have a material impact on its ability to achieve your business outcomes.

Step 8 : Schedule the issues and internally agree the approach

By our undertaking the first seven Steps, this will provide a much clearer idea of what we suggest you need to communicate to your supplier, so you can start to rebuild the relationship.

This evidence and the approach will be discussed with your internal stakeholders so it can all be critical friend challenged between us. From this, we’ll agree a systematic approach to the supplier that has ‘one voice’.

The evidence compiled will consist of:

- A basic chronology of events from the inception of the relationship. This will include the background to why you selected the supplier and felt comfortable with its expertise.

- It will explain the specifics of what you perceive to have gone wrong, the evidence that supports these perceptions and the work undertaken to review the evidence to assure the supplier the review has been completely independent and objective.

- Next, your objectives in raising these issues will be stated. It will explain the business outcomes you would like to achieve by rebuilding the relationship and why you want this relationship to work.

- We’ll also detail the behaviours you all think need to change, by both you and the supplier.

- It will set out the time-frames by which you would like to start rebuilding trust with your supplier, and state that you would like to work with them to determine how to measure the success of that rebuilding.

- Finally, it will give dates when your senior officers will be available to meet the supplier, to agree how to move the relationship forward.

Key attributes of the BPG Service Improvement team

Dispute Expert and Behavoural Observer

Observe participant’s behavior; encourage engagement; assure contractual compliance; assure supplier remains accountable for solution fitness for purpose.

Senior Business Analyst

Assures issues for resolution; clarifies user operating scenarios (use cases); offers up ‘the art of the possible’ for resolution.

Lead Elicitor/Encourager/Warm Engager

Puts people at ease; asks very insightful questions of participants; participants feel their contribution is critical.

Defining Service Improvements is only one element of the BPG ‘Optimise’ method

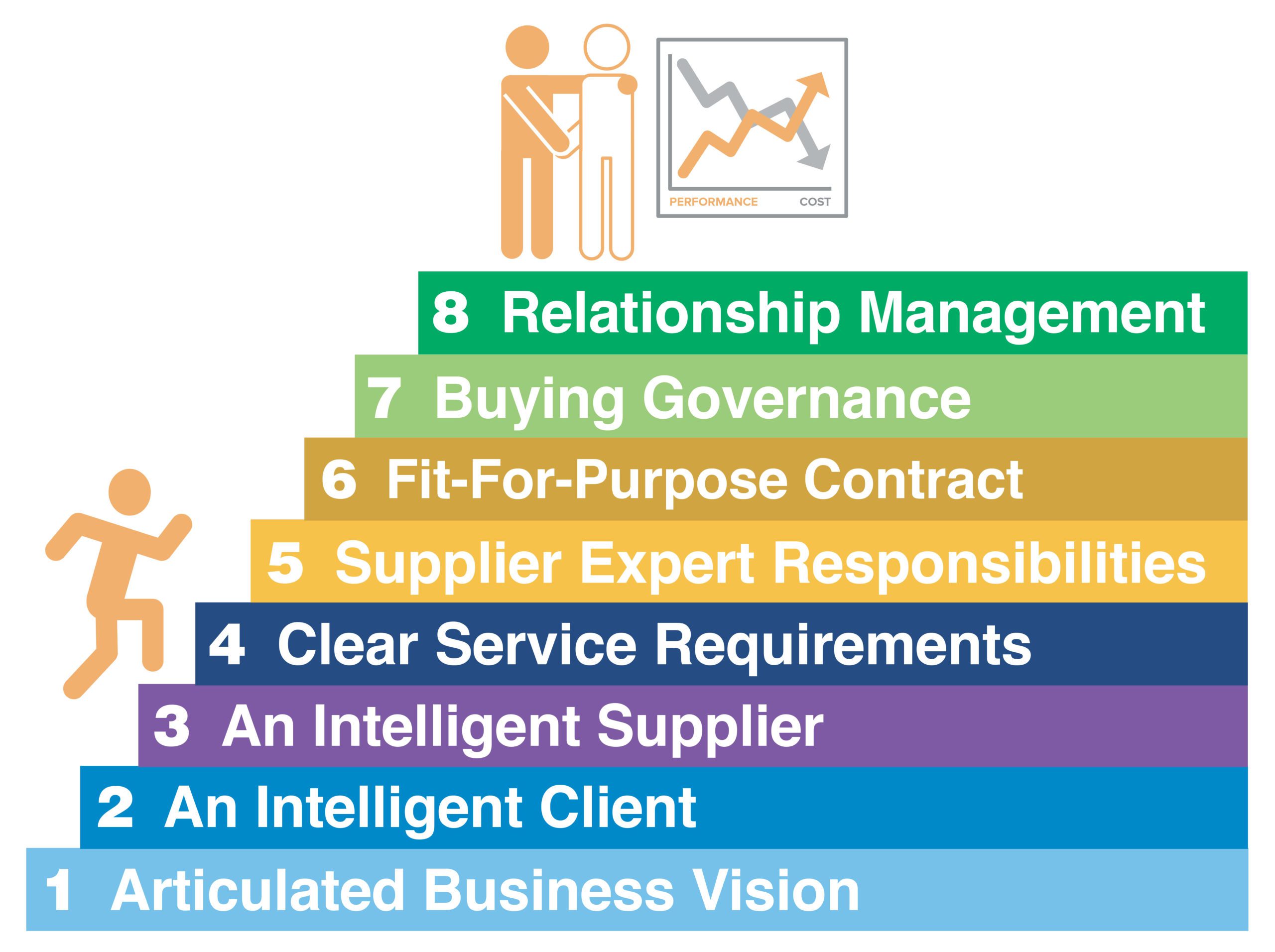

Evidenced by over 500 complex relationships, it can be implemented quickly to improve service innovation and drive down BAU costs

Share Great Practice

Experience of over 500 complex supplier relationships, means we can share great practice with you that really works.

Drive maximum value

Defining Service Improvements helps support the 10 characteristics that drive maximum value in complex supplier relationships.

A brilliant project outcome

This is part of the ‘Optimise’ process; a proven method assuring a brilliant project outcome and an excellent supplier relationship.

5 steps to a great new relationship

See the 5 steps to making sure new complex supplier relationships work really well.

Clients that we support

Most of our clients are already highly experienced in complex supplier relationships. Click here to see how we help them take complex supplier relationships to the next level.